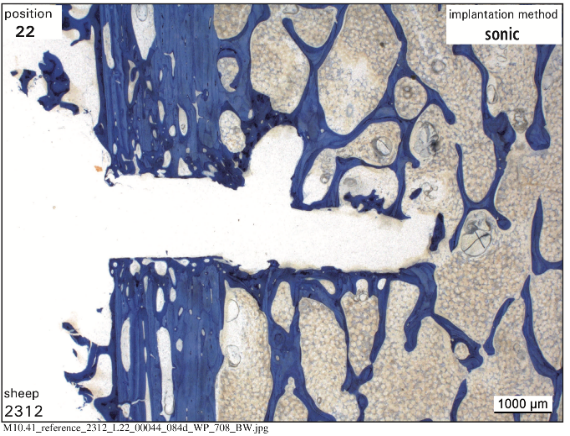

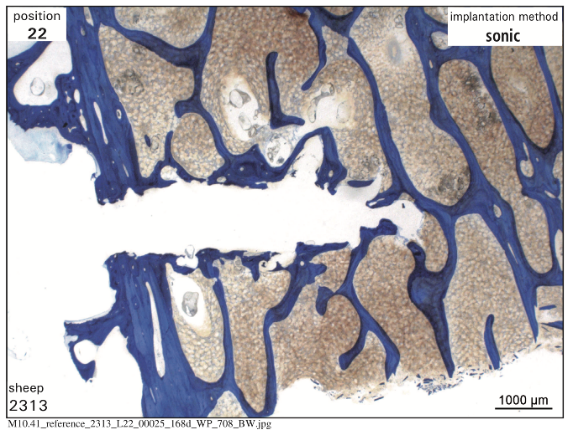

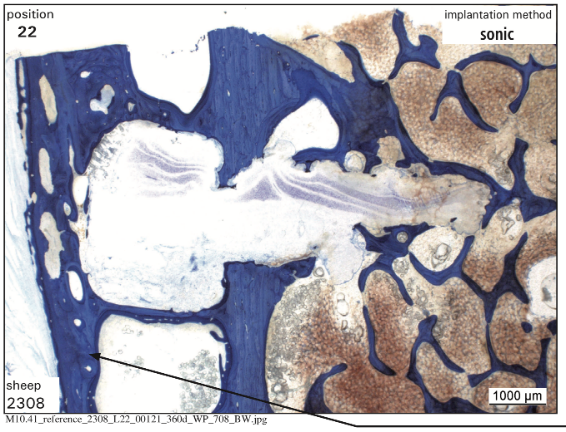

Product Development Engineer at VetWelding

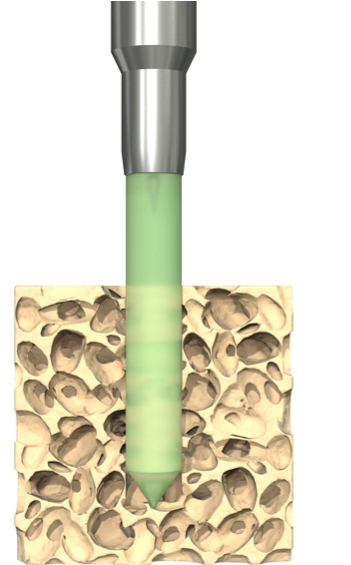

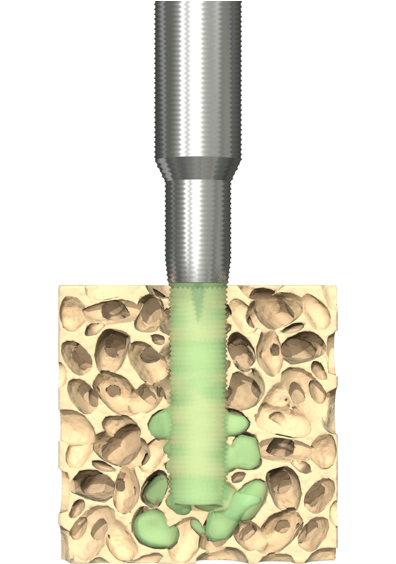

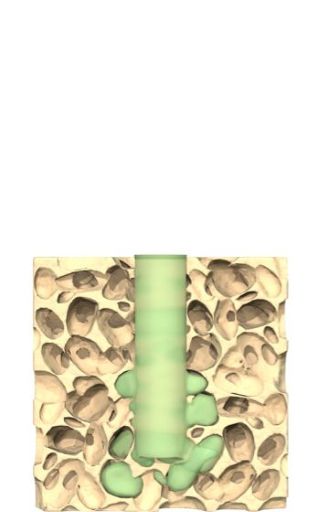

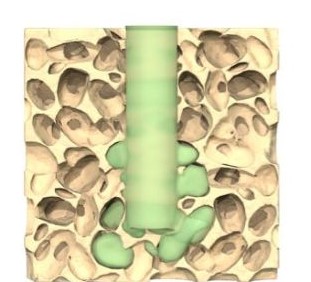

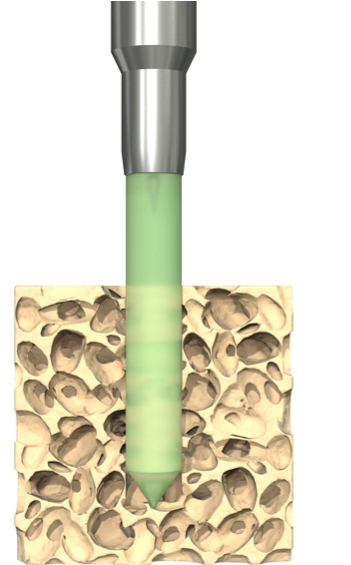

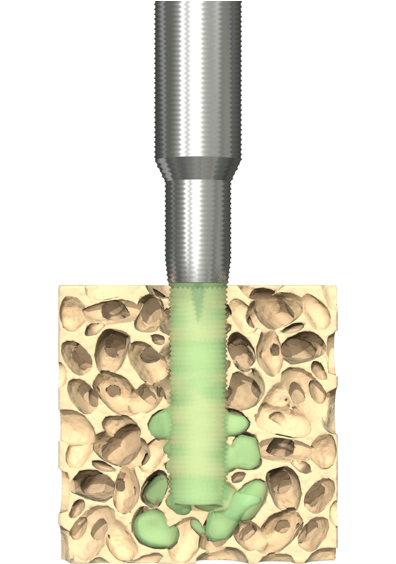

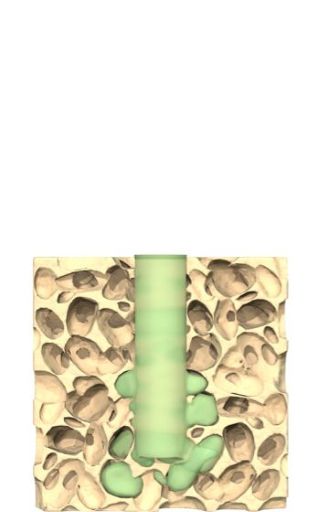

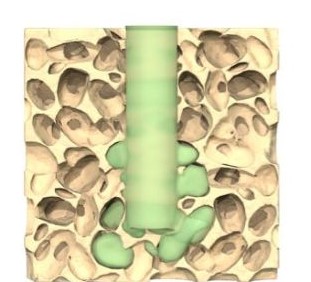

I find our BoneWelding technology inspiring; it is so simple for a surgeon to apply and yet brilliantly stable in so many different bone structures. I also like that this cutting edge technology can be used in veterinary medicine. I love animals and am happy that with our work and development, pets will have better solutions if they are in need of an anchor or a plate.